Omni Finishing

Omni Finishing163 Railroad Drive

Ivyland, PA 18974

Phone: 800 220 1075

Fax: 215 953 8644

Email: info@omnifinishing.com

Omni Finishing

Omni Finishing

| Items |

2636 Pro-Finish® Blast Cabinets |

3648 Pro-Finish® Blast Cabinets |

3660 Pro-Finish® Blast Cabinets |

3674 Pro-Finish® Blast Cabinets |

4848 Pro-Finish® Blast Cabinets |

|||||

| Interior Dimension | N/A 26 x 36 x 30 in | N/A 23 x 48 x 36 in | N/A 36 x 60 x 36 in | N/A 36 x 74 x 36 in | N/A 48 x 48 x 36 in | |||||

| Overall Dimension | N/A 28 x 42 x 70 in | N/A 38 x 54 x 72 in | N/A 38 x 66 x 72 in | N/A 38 x 80 x 72 in | N/A 50 x 54 x 72 in | |||||

| Door Opening Height | N/A 22 in | N/A 32 in | N/A 32 in | N/A 32 in | N/A 32 in | |||||

| Door Opening Width | N/A 20 in | N/A 29 in | N/A 29 in | N/A 29 in | N/A 41 in | |||||

| Standard Number of Doors | N/A 1 | N/A 2 | N/A 2 | N/A 2 | N/A 2 | |||||

| Ceramic Pressure Nozzle, Diameter | N/A 3/16 in | |||||||||

| Ceramic Suction Nozzle - Air Jet, Diameter | N/A 5/16 to 5/32 in | |||||||||

| Pressure - Suction Piping, Diameter | N/A 1-1/2 in | |||||||||

| Reclaimer Ventilation Rate | N/A 400 ft³/min600 ft³/min | N/A 400 ft³/min600 ft³/min | N/A 600 ft³/min900 ft³/min | N/A 900 ft³/min | N/A 600 ft³/min900 ft³/min | |||||

| Exhaust Fan Motor | N/A 1 hp | N/A 1 hp1-1/2 hp | N/A 1-1/2 hp2 hp | N/A 2 hp | N/A 1-1/2 hp2 hp | |||||

| Pro-Finish® Options |

N/A

|

|||||||||

| Standard Features |

N/A

|

|||||||||

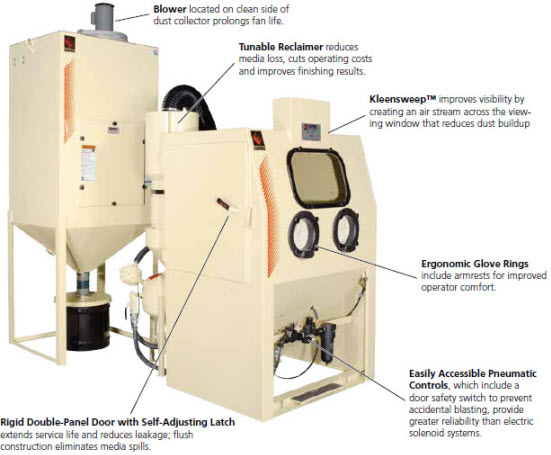

| Pro-Finish Blast Cabinet Features |

N/A

Pro-Finish-Blast-Cabinet-Features |

|||||||||

|

|

||||||||||